India is witnessing a major shift toward sustainable energy solutions, and biomass briquettes and pellets are emerging as powerful contributors to this transition. As a crucial Waste-to-Energy initiative, biomass fuel not only promotes clean energy but also addresses one of India’s biggest challenges—managing huge volumes of agricultural residue. Every harvesting season, millions of tons of crop waste are generated across the country. Instead of being burnt in fields, this residue can be converted into valuable energy fuel, supporting both environment protection and rural economies.

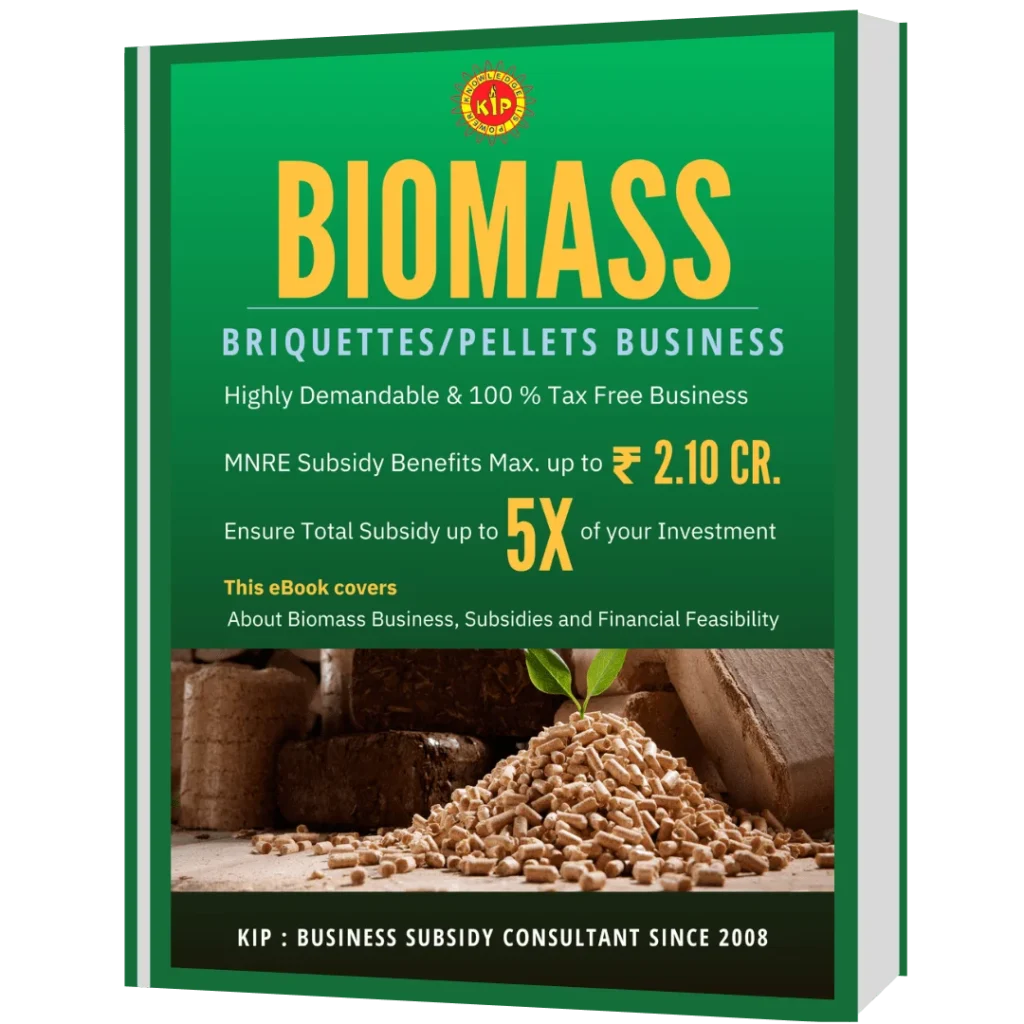

Biomass Briquettes & Pellets: A Fast-Growing Green Business in India

What Is Biomass Fuel?

Biomass briquettes and pellets are solid, compact fuel blocks produced from organic waste, mostly agricultural residues. These include paddy straw, mustard husk, cotton stalk, maize cobs, forest clippings, and horticulture waste. By converting these low-value waste materials into high-density fuel, biomass processing unlocks a renewable energy source that can be produced locally and supplied continuously. Unlike coal, biomass emits significantly lower pollutants and aligns with India’s climate commitments, making it highly suitable for industries looking to reduce carbon emissions.

Biomass vs. Coal: A Quick Comparison

| Factor | Coal | Biomass Briquettes/Pellets |

|---|---|---|

| Pollution | High | Low |

| Ash Content | 15%–30% | 6%–10% |

| Cost | Expensive | Less Expensive |

| Wastage | 15%–20% | 8%–10% |

Biomass fuels offer an eco-friendly, low-ash, and cost-effective alternative to coal. The easier handling and storage, along with reduced wastage, make biomass a preferred energy source for industries that are exploring cleaner and more economical fuel options.

Massive Demand & Mandatory Consumption

Huge Market Demand Gap

India needs nearly 95,000 tons of biomass fuel every day, but current production capacity is only 8,000–10,000 tons per day.

This massive gap creates a strong opportunity for new biomass manufacturing units.

Government Policy Boost

On 11 July 2023, the Ministry of Environment, Forest and Climate Change mandated that all coal-based thermal power plants must use at least 5% biomass (pellets or briquettes) blended with coal.

Over 208+ thermal power plants are operating nationwide.

60+ plants have already begun co-firing biomass.

Major companies like NTPC, Adani Power, Vedanta are actively issuing tenders for biomass pellets.

Industries Using Biomass Fuel

Besides power plants, the following industries are switching to biomass due to cost and environmental advantages:

Textile Mills

Paper Mills

Food & Food Processing Units

Chemical Plants

Dyeing & Leather Industries

The Financial Edge: Subsidies, Tax Benefits & Funding

Starting a biomass briquette or pellet plant becomes much easier because the government offers strong financial support. These benefits reduce setup cost and increase overall profit.

1. 100% Income Tax Exemption (Section 80JJA)

100% tax deduction on profits for 5 years

Available for all waste-to-energy units

2. MNRE Capital Subsidy (Updated July 2024)

MNRE provides capital subsidy based on plant capacity, which directly reduces your project investment.

Subsidy Rates:

| Plant Type | Subsidy per MTPH | Max Subsidy (5 MTPH) |

|---|---|---|

| Briquette Plant | ₹9.0 lakh | ₹45 lakh |

| Non-Torrefied Pellet Plant | ₹21.0 lakh | ₹1.05 crore |

| Torrefied Pellet Plant | ₹42.0 lakh | ₹2.10 crore |

Why torrefied pellets get more subsidy?

They have higher energy value, very low moisture, and better storage/transport performance.

3. Funding Support: AIF + CGTMSE

The Agri Infrastructure Fund (AIF) further supports entrepreneurs with:

3% interest subvention for loans up to ₹2 crore

Collateral-free loans through CGTMSE coverage

How KIP Can Help You

KIP makes the entire process of setting up a biomass briquette or pellet plant easier, faster, and more profitable. Our team guides you at every step—from understanding government policies to securing subsidies and preparing all required documents. We ensure you get maximum financial benefits with minimum effort.

Project Feasibility & SVR Reports:

We prepare detailed subsidy viability reports to show your project’s eligibility, benefits, and financial returns.Subsidy Consultation:

Our experts identify all central and state-level subsidies such as MNRE CFA, tax exemptions, and other incentives.Documentation & Application Support:

We handle complete paperwork, compliance, and online submissions so you avoid delays or rejections.End-to-End Guidance:

From planning the plant capacity to understanding raw material sourcing and buyer demand, we guide you throughout the project.Fast & Hassle-Free Process:

With our experience in renewable energy projects, we ensure smooth execution and quick subsidy disbursement.

Frequently Asked Questions (FAQs)

Q1: Is biomass briquette/pellet business profitable?

Yes, due to high demand and government support.

Q2: What is the basic investment required?

Around ₹25–40 lakh for small units.

Q3: What raw materials are used?

Agri waste like husk, straw, sawdust, and bagasse.

Q4: Who buys biomass fuel?

Thermal power plants and steam-based industries.

Q5: What subsidies are available?

100% tax exemption + MNRE capital subsidy.

Q6: Do I need special approvals?

Only basic industrial permissions and pollution NOC.

Tags

#Agro Waste Utilization

#Biofuel

#Biofuel Manufacturing

#Biomass Briquettes

#biomass business

#Biomass Fuel Advantages

#Biomass Industry Opportunities

#Biomass Market Demand

#biomass pellets

#BiomassBriquettes

#BiomassBusiness

#BiomassPellets

#Briquetting Plant

#Clean Energy Solutions

#CleanEnergy

#Green Energy Business

#GreenEnergyIndia

#MSME Green Business Ideas

#pellet plant India

#Renewable Energy India

#RenewableEnergy

#Sustainable Energy Startup

#SustainableBusiness

#Waste-to-Energy Projects

Biomass

Biomass  Warehouse

Warehouse  Msme services

Msme services  Diary & Milk Processing

Diary & Milk Processing  Agro-Base Business

Agro-Base Business  Business Registration

Business Registration  Tender Updates

Tender Updates

Home

Home  Whishlist

Whishlist  Checkout

Checkout  Account

Account